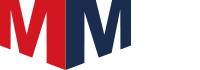

TW and BW Reverse Osmosis Systems consist of sophisticated water treatment units for industrial and professional applications where the need for high quality requires robustness, low energy footprint, high performance and long-lasting use.

Reverse Osmosis

Overview

BW and TW series, combined with the pre-treatment system in a common frame with interconnected functions, can be a complete and affordable solution for the production of clean water! The architecture of the unit requires minimal hydraulic lines, less space and easy access for maintenance.

In conclusion, this is a high quality system with no leaks and damage, maximum space utilization and easy maintenance. All the parts that are incorporated are characterized by high quality as they come from large world-class houses with decades of experience.

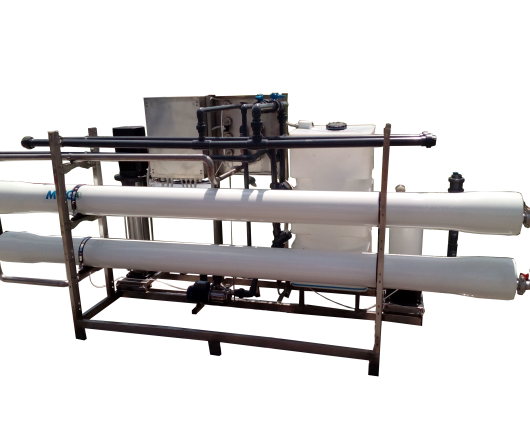

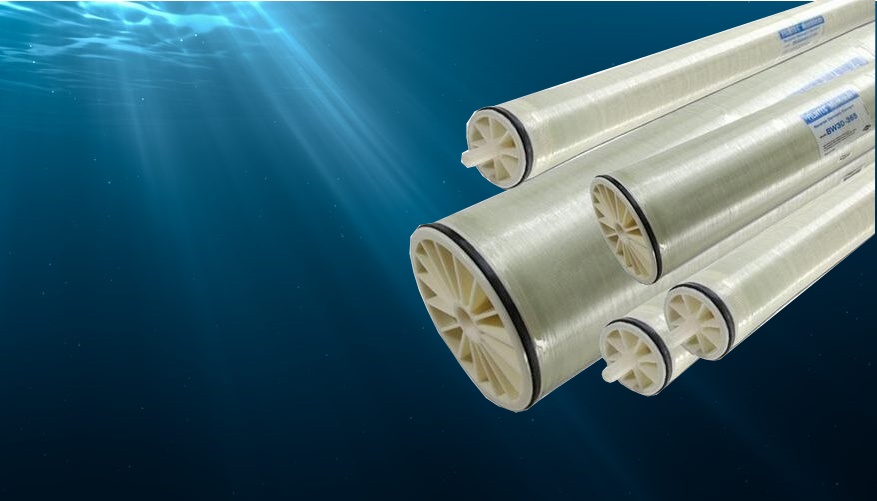

Membranes

Depending on the characteristics of the inlet water and after appropriate pretreatment, the role of the membrane is to maintain the quality of clean water at acceptable levels. New technology membranes with excellent permeability, high levels of discharge and low energy consumption ensure a high performance system capable of delivering as much water as possible, with lower consumption.

High Pressure Pump

Rotary blade pumps are energy efficient but need more maintenance. Stainless steel pumps are used exclusively by EU electric motors. Multistage pumps are commonly used on larger scale systems due to their long service life and their ability to adapt to variations in flow. All multi-stage pumps have at least their moving parts made of stainless steel

Control Panel

The control panel is located at the top right of the system and is responsible for all the actions that take place in the system. It is made of ABS IP 55 (at least), they protect and control each individual device.{/The PLC is LOGO! Siemens and checks all available system signals. You may also have a conductivity controller integrated with the results displayed directly on the screen while the ETHERNET expands control limits to a global scale! The same screen shows all system functions, such as membrane rinsing, storage tank completeness, thermal protection, intermittent voltage, volume, and so on.

Technical Data

General

- Inlet pressure:1-4 bar

- Power:24Vdc Secondary Circuit

- Power:Built-in Conductivity Meter

- Other:Embedded Electronic Feature Meters (V, A, W)

- Operation:PLC LOGO! Siemens

- Frame:Stainless Steel

Temperature

- Water:16-35 ο C

- Ambient:5-45 ο C

Installation Sectors