The European standard EN1284 comes to set new data in the automatic fire extinguishing of buildings & industry radically changing many of the parts of a typical automatic fire extinguishing system as we know it to date.The specifications set by the new standard change all parts of the installation as well as the heart of the system that is the fire pump

EN12845

Overview

BRENTAS PC as a fire fighting manufacturer, following the technological developments, has successfully advanced the construction of fire pumps under the new standard since 2009.The companies that trusted us to build their fire pumps had the opportunity to watch the construction, the quality of the materials and the start of the fire pumps by the technical staff of our company at the site of their installation.

Pumps within EN 12845

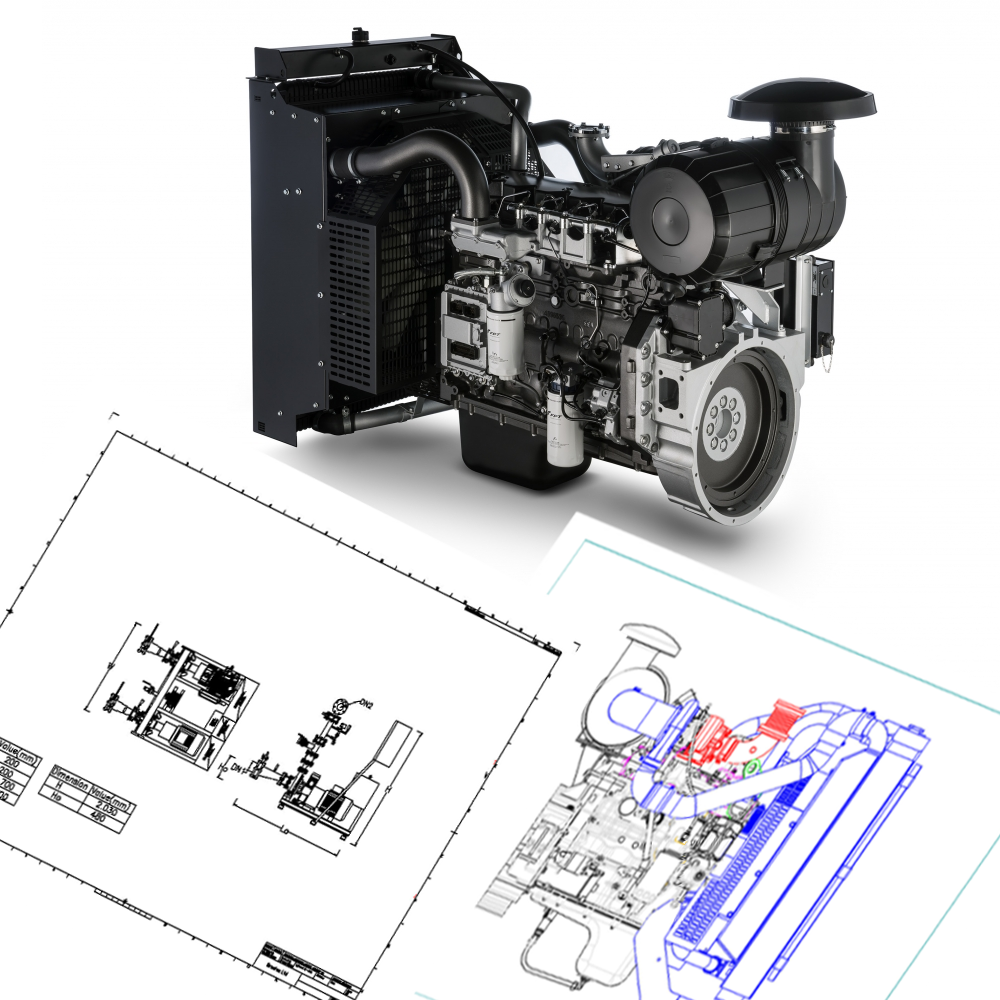

Architecture conforming with every specification

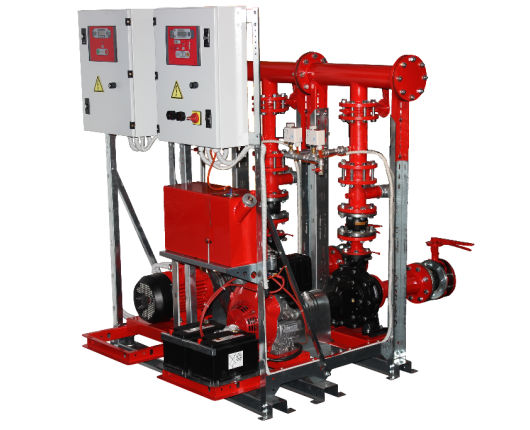

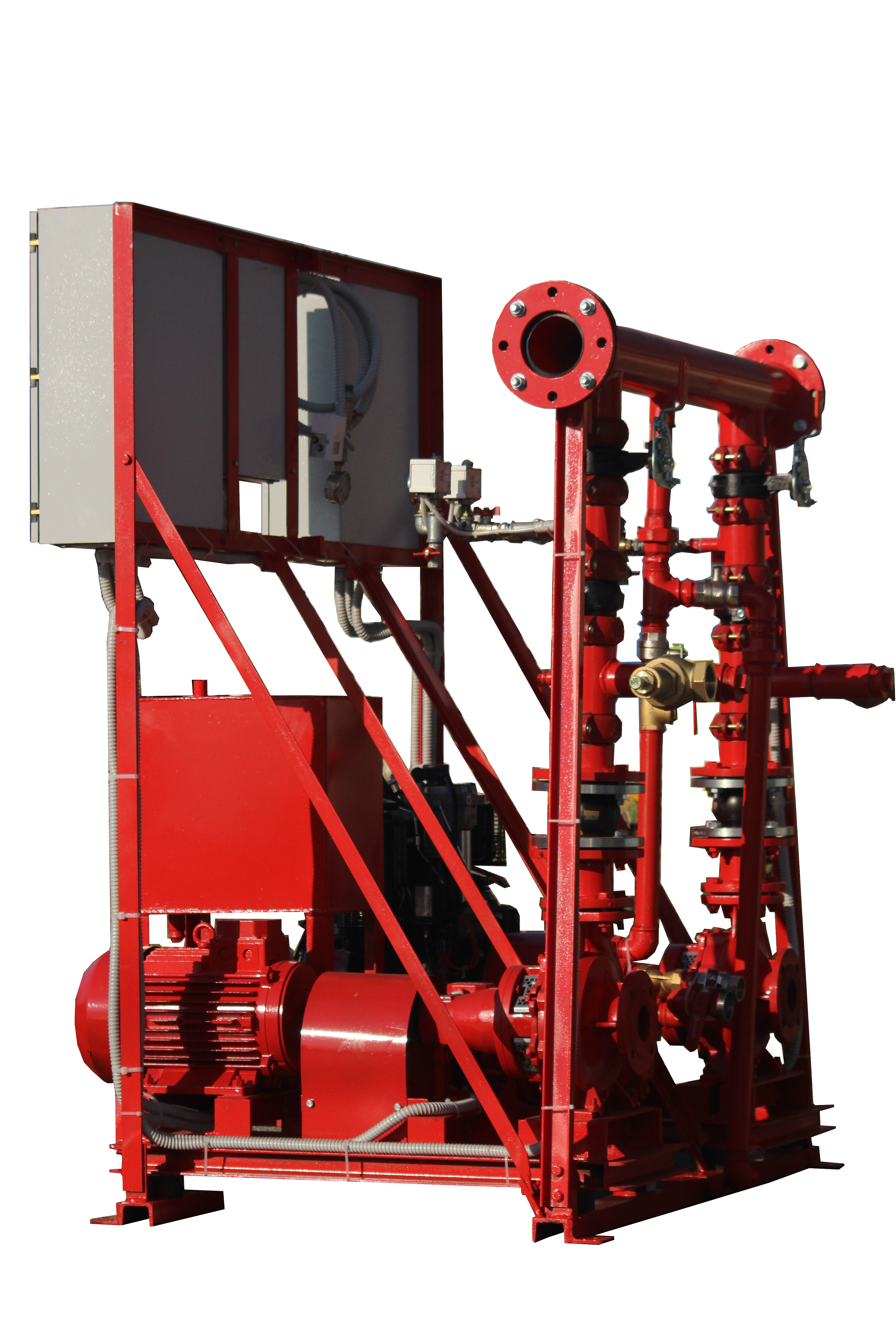

For each machine, double batteries and chargers are used, a common depression collector, a pay-meter with dual pressure and pressure gauges, a 6-hour fuel tank, and many other devices and appliances that make the final set up, quality and functional. All machines are of European origin as required by the standard. The architecture of the machine is designed to have a compact construction that does not sacrifice ease of maintenance while meeting all specifications.

Guarantee in quality

The fire pumps made by BRENTAS PC is delivered complete with all necessary certification mounted on a single frame on anti-shock treads and is hydraulically and electrically ready for installation, so that the hydraulic installation with the respective grid and the electrical supply from the main panel or the possible generator. Also the technical department of BRENTAS PC is staffed by experienced technicians with the ability to provide coverage of all types throughout Greece, Cyprus and the Balkans. A fire brigade of our company has an excellent quality - cost ratio with unparalleled after sales service with a written guarantee of quality.

Technical Data

General

- Pressure vessel:A pressure vessel of suitable capacity.

- Links:Antiradal links on the side of depression.

- Operation:Autonomous starting circuit of the diesel pump station with two independent accumulators.

- Starting circuit:Double starter motor relay.

- Other:Engine stop device from the earthed panel ( Electric Stop).

- Recirculation kit:For each pump which allows a minimum flow rate to prevent overheating of the pump if it is operated with the discharge valve closed.

- Pressure collector:For main pumps, which includes connection pipes with the discharge manifold and recirculation circuit.

- Fuel tank:Independent fuel tank of sufficient capacity for lit for supply of the diesel engine.

- Non-return valve:Non-return valve, flanged, with inspection port on the side of each pump's depression.

- Pressure gauge:On the depression side, for each pump, between check valve and valve.

- Frame:Specially treated and painted after the epoxy painting of a metal support frame, for the installation of the pump automation panels.

- Valves:Throttle type lever with lever on the depression side of each pump.The valves include self-monitoring of their status (ON / OFF).

- Flow meter kit:To control pump performance during tests and periodic inspections.

- Pressure switches:Two differential for each pump.

Installation Sectors